Engineers at MIT have introduced a revolutionary laser-based approach, named LIRAS, for examining the dynamic qualities of metamaterials without damaging them. This method employs dual lasers to generate and measure vibrations, providing deeper insights into materials such as polymers at the micro level. This breakthrough could herald significant advancements in areas like ultrasound technology and protective gear, and may expedite the creation of acoustic lenses, impact-resistant films, and other innovative materials.

Metamaterials, a marvel of engineering, are crafted from common materials like polymers, ceramics, and metals. When meticulously designed at the microscale, these ordinary substances acquire remarkable capabilities.

Engineers use computer models to experiment with various microstructures, exploring how they can be transformed into products like sound-focusing lenses or lightweight, bulletproof films.

However, simulations have limitations. Physical testing is essential to verify the performance of metamaterials. Previously, testing at the microscale was challenging without causing damage to the structures.

New Laser-Based Approach

MIT engineers have now developed a non-invasive, efficient method to rapidly identify promising metamaterials for practical use.

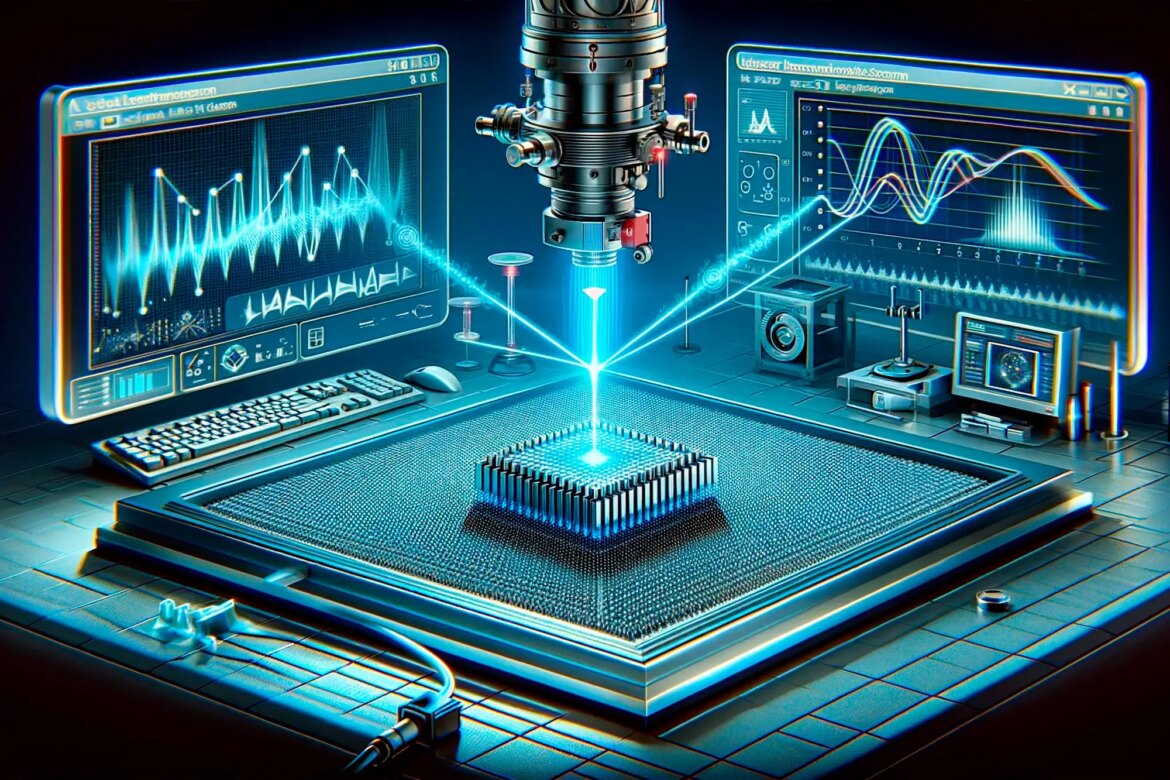

This method uses a pair of lasers: one to stimulate a structure, and another to record its vibrational response, akin to ringing a bell and capturing its echo, but without any physical contact. This approach can induce vibrations in the minute components of a metamaterial, simulating physical impacts or strains.

An optical micrograph illustrates a collection of microscale metamaterial samples on a reflective base, with laser pulses visually represented as red (pump) and green (probe) pulses examining a central sample. The LIRAS technique can analyze all samples on the base within minutes.

Dynamic Material Analysis

The resulting vibrations from this technique allow engineers to deduce various dynamic characteristics of the material, like its response to impacts and its interaction with sound. With rapid laser pulses, they can examine hundreds of miniature structures swiftly. This method presents a non-destructive, reliable, and efficient means of analyzing microscale metamaterials.

Practical Applications and Research

Carlos Portela, the Brit and Alex d’Arbeloff Career Development Professor in Mechanical Engineering at MIT, emphasizes the need for faster testing and optimization of these materials. His team’s research, soon to be published in Nature, includes contributions from Yun Kai, Somayajulu Dhulipala, Rachel Sun, Jet Lem, Thomas Pezeril, and Washington DeLima at the Department of Energy’s Kansas City National Security Campus.

Fabrication and Testing Challenges

Portela and his team create metamaterials from common polymers, 3D-printed into tiny, scaffold-like structures. These are designed by repeating a single geometric unit to grant the polymer unique properties.

Nanoindentation is the traditional method for testing such structures, which involves a micrometer-scale tip pressing down on the structure. However, this method can be slow and potentially damaging.

A New Approach with Lasers

The team explored laser ultrasonics, a non-destructive technique using short laser pulses at ultrasound frequencies. This method can excite thin materials like gold films without physical contact. They adapted this technique for their 3D-printed metamaterial towers, similar in size to thin films.

Yun Kai, an expert in laser optics, developed a setup with two ultrasonic lasers: one to stimulate the metamaterial samples and another to measure their vibrations. They tested this approach on hundreds of microscopic towers with varying architectures and heights, identifying distinct vibrational patterns for each.

Applications and Future Directions

This technique was also used to detect defects in the towers. Towers with varying defects showed shifted vibrational signatures, suggesting potential applications in quality control.

Portela anticipates this laser setup will accelerate the discovery and testing of practical metamaterials. His focus includes developing materials for enhancing ultrasound technology and creating impact-resistant materials, like lining for bike helmets.

Kai highlights the importance of understanding the dynamic behavior of metamaterials, opening up possibilities for extreme exploration.

The study, titled “Dynamic Diagnosis of Metamaterials via Laser-Induced Vibrational Signatures,” will be published in Nature. The research received support from the Department of Energy’s Kansas City National Security Campus, the National Science Foundation, and DEVCOM ARL Army Research Office through the MIT Institute of Soldier Nanotechnologies.

Table of Contents

Frequently Asked Questions (FAQs) about Laser-Based Metamaterial Testing

What is the new method developed by MIT engineers for testing metamaterials?

MIT engineers have developed a novel laser-based method called LIRAS, which allows for the testing of the dynamic properties of metamaterials without causing any damage. This method utilizes two lasers to create and measure vibrations in the materials, facilitating a deeper understanding of their microscale properties.

How does the laser-based technique work in testing metamaterials?

The technique involves using one laser to excite the metamaterial structures and another to measure the vibrations caused by this excitation. This process is akin to striking a bell and recording its reverberation, but with lasers instead of physical contact, allowing for non-destructive testing.

What are the potential applications of this new testing method?

This breakthrough has significant implications for advancing ultrasound technology and protective gear. It could also speed up the development of acoustic lenses, impact-resistant films, and other innovative materials.

What are metamaterials and how are they unique?

Metamaterials are engineered materials made from common substances like polymers, ceramics, and metals. When designed precisely at the microscale, these materials can exhibit extraordinary properties that are not found in their conventional forms.

How does this method compare to traditional testing techniques?

Traditional testing methods like nanoindentation physically interact with the material, which can be slow and potentially damaging. The new laser-based method is faster, non-destructive, and allows for dynamic testing, providing a more comprehensive understanding of the material’s properties.

More about Laser-Based Metamaterial Testing

- MIT News: New Laser Method for Testing Metamaterials

- Nature Journal: Latest Research on Metamaterials

- Laser Technology and Material Science Research

- Advancements in Ultrasound Technology

- Metamaterials: Engineering and Applications

5 comments

interesting read, but I’m a bit skeptical. How can lasers really test materials without touching them? Sounds like science fiction to me.

I read something similar in Nature Journal, these metamaterials could revolutionize everything from medical devices to sports gear. Exciting times.

wow, this is a game changer for materials science! MIT always comes up with such innovative stuff.

the article is good, but it’s a bit technical for a layperson like me. Wish they explained it in simpler terms.

Super cool! This kind of tech development is what keeps pushing our boundaries forward, MIT is on the forefront again.