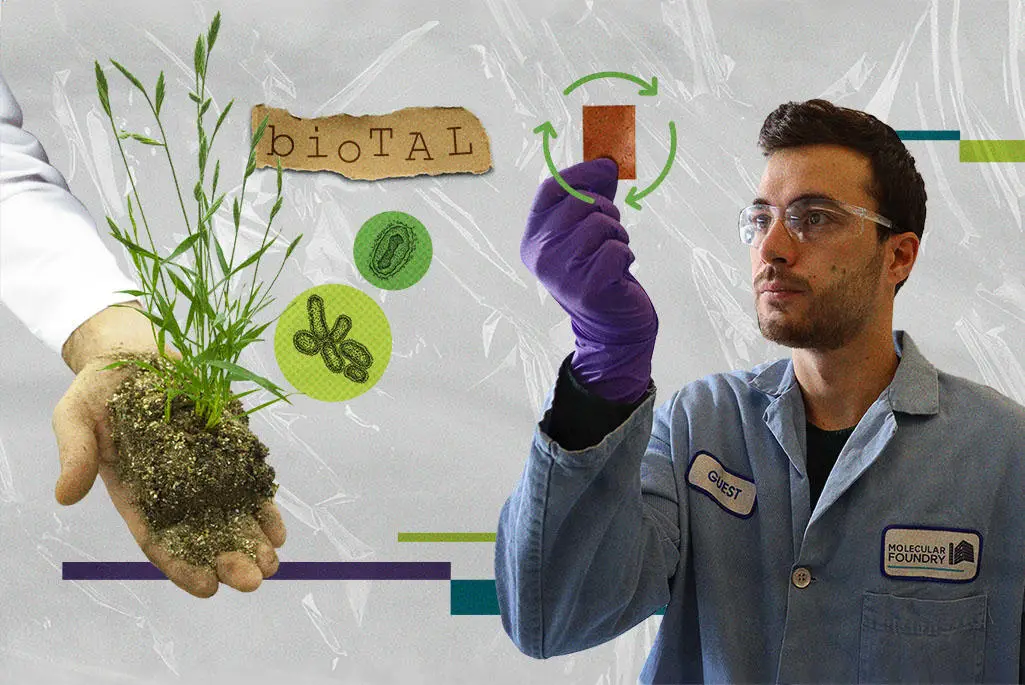

A breakthrough by Berkeley Lab researchers entails the use of bacteria for the creation of biorenewable and recyclable plastics. Credit: Jenny Nuss/Berkeley Lab

Scientists have triumphed in genetically modifying microbes to yield raw materials for recyclable plastics. This offers a green alternative to non-renewable and polluting petrochemicals.

The considerable environmental challenge posed by plastic waste is due to most plastics being non-recyclable and manufactured from finite, harmful petrochemicals. But change is on the horizon, with scientists successfully modifying microbes to generate biological substitutes for the foundational materials in poly(diketoenamine) or PDK plastic, which can be recycled endlessly.

This pioneering discovery was recently announced in Nature Sustainability and is the product of a collaboration involving experts from three facilities at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab): the Molecular Foundry, the Joint BioEnergy Institute (JBEI), and the Advanced Light Source.

Brett Helms, a staff scientist at the Molecular Foundry who spearheaded the project, said, “This marks the first instance of bioproducts being utilized to create a predominantly bio-based PDK, as well as the first instance of a bio-advantage over petrochemicals in terms of the material’s characteristics and the expense of large-scale production.”

Unlike traditional plastics, PDK can be consistently broken down into its original building blocks and reconstructed into new items without any quality deterioration. Initially, PDKs used building blocks sourced from petrochemicals, but these components can now be redesigned and created through microbes. After four years of collaborative effort, the team has manipulated E. coli to convert plant sugars into one of the precursor materials – a molecule known as triacetic acid lactone or bioTAL – resulting in a PDK with approximately 80% bio-content.

Raw bioTAL (left) can be merged with other chemicals to process into a biorenewable, recyclable PDK plastic (right). Credit: Jeremy Demarteau/Berkeley Lab

Project scientist Jeremy Demarteau, who is part of the biopolymer development team, commented, “We’ve proven that creating 100% bio-content in recyclable plastics is achievable. Expect more of this from us in the future.”

PDKs can be employed in numerous products, including adhesives, flexible objects like computer cables or watch straps, building materials, and “tough thermosets” – rigid plastics created through a curing process. The researchers were pleasantly surprised to find that the integration of bioTAL into the material increased its working temperature range by up to 60 degrees Celsius compared to the petrochemical version. This paves the way for using PDKs in items requiring specific operating temperatures, such as sports equipment and car components like bumpers or dashboards.

Tackling the plastic waste issue

The United Nations Environment Program predicts that global plastic waste production is around 400 million tons annually, and this figure is expected to exceed 1 billion tons by 2050. Out of the 7 billion tons of plastic waste already generated, only approximately 10 percent has been recycled, with the majority ending up in landfills or incinerated.

Jay Keasling, a professor at UC Berkeley, a senior faculty scientist at Berkeley Lab’s Biosciences Area, and the CEO of JBEI, stated, “We can’t continue to exhaust our finite fossil fuel resources to cater to this relentless demand for plastics. Our aim is to help tackle the plastic waste problem by developing materials that are both biorenewable and circular, and enticing companies to adopt them. This allows people to use the products they require for the duration they need them, before those items are repurposed into something new.”

The current study also builds upon a 2021 environmental and technological assessment, which revealed that PDK plastic could compete commercially with traditional plastics if mass-produced.

Corinne Scown, a staff scientist in Berkeley Lab’s Energy Technologies Area and a vice president at JBEI, added, “Our new findings are extremely promising. We discovered that even minor enhancements to the production process could soon enable us to manufacture bio-based PDK plastics that are not only more cost-effective but also less carbon-emitting than those derived from fossil fuels.”

These enhancements encompass accelerating the rate at which microbes convert sugars to bioTAL, employing bacteria capable of transforming a broader array of plant-derived sugars and compounds, and running the facility on renewable energy.

This work, titled “Biorenewable and circular polydiketoenamine plastics” by Jeremy Demarteau and his colleagues, published on July 27, 2023, in Nature Sustainability, was supported by the Department of Energy’s Bioenergy Technologies Office.

The Molecular Foundry specializes in nanoscale science and is a user facility of DOE Office of Science, Office of Basic Energy Sciences. The Joint BioEnergy Institute (JBEI) is a Bioenergy Research Center funded by DOE’s Office of Science. The Advanced Light Source is also a user facility of the DOE Office of Science.

Table of Contents

Frequently Asked Questions (FAQs) about Biorenewable Plastics

What is the key innovation in the research conducted at the Berkeley Lab?

Scientists at the Berkeley Lab have successfully engineered bacteria to produce ingredients for recyclable plastics, specifically poly(diketoenamine), or PDK plastics, providing a sustainable substitute to finite and polluting petrochemicals.

What is unique about the PDK plastic developed?

Unlike traditional plastics, PDK plastic can be deconstructed into its original building blocks and reconstructed into new products without any loss in quality. Additionally, the base materials of PDKs, which were previously derived from petrochemicals, can now be created using bacteria.

How is the production process for the new PDK plastic improved?

The researchers were able to manipulate E. coli bacteria to convert plant sugars into one of the starting materials for PDK plastic, namely triacetic acid lactone (bioTAL), which resulted in a PDK with approximately 80% bio-content. Future improvements include increasing the conversion speed of sugars to bioTAL and using bacteria that can process a wider range of plant-derived sugars.

How can the new PDK plastics help solve the global plastic waste problem?

The PDK plastics can be recycled endlessly without any loss in quality, unlike most traditional plastics. By replacing finite and environmentally damaging petrochemicals with bacteria-produced bio-materials, this innovation provides a sustainable and circular solution to the problem of plastic waste.

Where can the findings of this research be found?

The details of this research were published in an article titled “Biorenewable and circular polydiketoenamine plastics” in the journal Nature Sustainability on July 27, 2023.

More about Biorenewable Plastics

- Berkeley Lab

- Nature Sustainability Journal

- Joint BioEnergy Institute (JBEI)

- Department of Energy’s Bioenergy Technologies Office

- United Nations Environment Program

- Molecular Foundry

6 comments

Love this! the potential here is massive, but lets not forget we also need to cut down on consumption. reduce, reuse AND recycle, folks!

Wow this is mind-blowing! Imagine a world where plastics are actually sustainable and we’re not constantly polluting the earth. This could be game changing!

thats pretty cool but how will they scale this? seems like a lot of work for bacteria to do lol

so can i recycle my plastic water bottle infinitely now? seems to good to be true. But if it’s real, it’s a huge leap forward.

impressive stuff, never thought i’d see bacteria as the heroes of the day 😀 way to go, science!

Finally, some hope in the fight against plastic pollution. Lets get behind this people, spread the word. The future is green!