MIT researchers have achieved a groundbreaking development in sustainable aviation fuel production by converting lignin, a byproduct of plant biomass, into 100% sustainable jet fuel. This innovative approach holds the potential to revolutionize the aviation industry by providing a renewable alternative to traditional fossil fuels.

The need for sustainable aviation fuel arises from the substantial carbon dioxide emissions generated by the transportation sector, with aviation being a significant contributor. Despite advancements in electric vehicles for ground transportation, aviation still relies heavily on liquid hydrocarbon fuels due to their superior energy density, crucial for long-distance flights.

Creating sustainable aviation fuels has been a challenge due to the stringent requirements imposed on aviation fuels, particularly in terms of chemistry and physical properties. These requirements are essential to ensure the safety and reliability of airplane engines, especially at high altitudes and low temperatures.

Aviation fuel is composed mainly of two types of molecules: aliphatic and aromatic. While aliphatic molecules are similar to those found in diesel fuels and can be derived from renewable sources, aromatic molecules are essential for maintaining the required properties of aviation fuel, including tight seals within the aircraft’s fuel system.

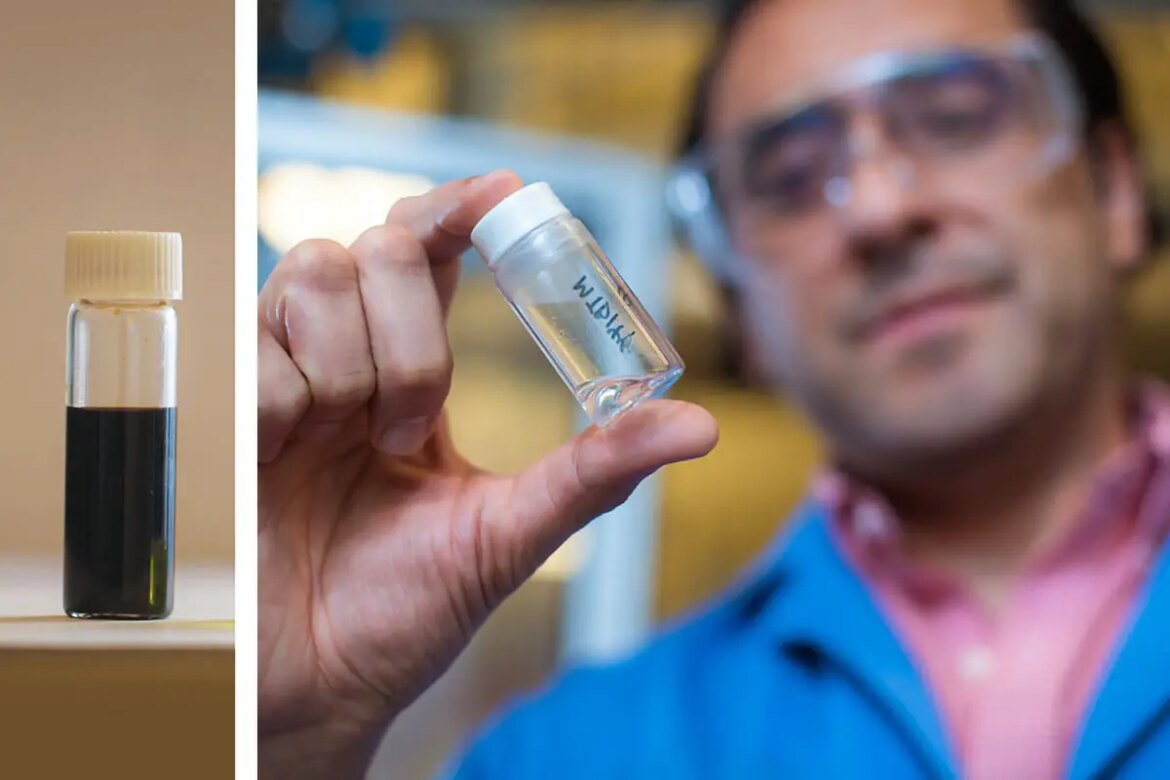

The breakthrough achieved by MIT researchers involves using a catalyst, specifically a molybdenum carbide catalyst, to convert lignin into aromatic molecules. Lignin, a complex plant material that makes up a significant portion of biomass carbon, is notoriously challenging to convert into useful products due to its chemical complexity. The key challenge was to break down lignin’s macromolecular structure into smaller fragments while eliminating oxygen atoms.

This process involves a two-step approach: first, the lignin is reacted with a ruthenium-based catalyst to produce lignin oil, which contains stable aromatic fragments. Then, the lignin oil is passed through a reactor containing the molybdenum carbide catalyst to remove oxygen atoms, resulting in the targeted aromatic molecules needed for aviation fuel.

Tests conducted on the resulting product have shown promising properties that align with aviation fuel requirements. However, further testing and certification are necessary to ensure that it meets the stringent standards for aviation fuel.

The potential impact of this research is significant. If the results can be replicated and scaled up, it could lead to the production of aviation fuel entirely derived from renewable sources, marking a crucial step toward achieving carbon-neutral aviation. Further research is underway to explore the application of this approach to different types of biomass, offering the hope of a sustainable and environmentally friendly future for the aviation industry.

Table of Contents

Frequently Asked Questions (FAQs) about Sustainable Jet Fuel

What is the key achievement of MIT’s research?

MIT researchers have successfully converted lignin, a byproduct of plant biomass, into 100% sustainable aviation fuel, which has the potential to revolutionize the aviation industry by offering a renewable alternative to traditional fossil fuels.

Why is sustainable aviation fuel important?

Sustainable aviation fuel is crucial for reducing the carbon footprint of the aviation industry, which is a significant contributor to global carbon dioxide emissions. It allows airplanes to fly while emitting fewer greenhouse gases, contributing to a more environmentally friendly aviation sector.

What are the challenges in producing sustainable aviation fuel?

Producing sustainable aviation fuel is challenging due to the strict requirements for aviation fuels, including specific chemistry and physical properties. Ensuring safety and reliability in aircraft engines at high altitudes and low temperatures is a primary concern.

How does MIT’s approach work?

MIT’s approach involves using a molybdenum carbide catalyst to convert lignin into aromatic molecules. Lignin, a complex plant material, is broken down into smaller fragments while eliminating oxygen atoms in a two-step process. This results in the creation of the targeted aromatic molecules needed for aviation fuel.

What are the potential benefits of this breakthrough?

If successfully scaled up and certified, this research could lead to the production of aviation fuel entirely derived from renewable sources, making a significant contribution to carbon-neutral aviation and reducing the industry’s environmental impact.

More about Sustainable Jet Fuel

- MIT News: “MIT’s Biomass Breakthrough: 100% Sustainable Jet Fuel From Plant Waste”

- Joule Journal: “Continuous hydrodeoxygenation of lignin to jet-range aromatic hydrocarbons”

- MIT Energy Initiative: Research on Sustainable Aviation Fuel

- Center for Bioenergy Innovation

- U.S. Department of Energy Office of Biological and Environmental Research

- Eni S.p.A.: MIT Energy Initiative

- Stanford University Department of Chemical Engineering

- National Renewable Energy Laboratory (NREL)

- Pacific Northwest National Laboratory

- Washington State University: Jet Fuel Combustion Lab

- MIT Energy Initiative: Research on Sustainable Aviation Fuel