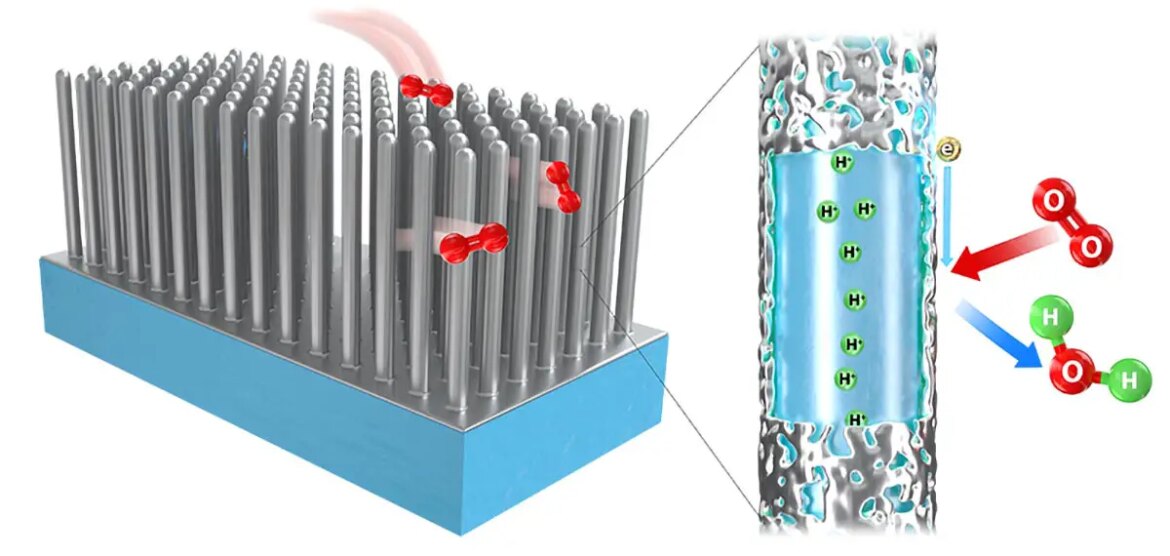

Electrodes furnished with vertically positioned coaxial nanowires facilitate proton transport via an ionomer core inside the nanowire. Electron movement in the exterior platinum nanofilm mingles with oxygen, thus culminating the fuel cell cathode reaction. Acknowledgment goes to LANL.

The Los Alamos National Laboratory has unveiled a fuel cell configuration that is remarkably resistant to corrosion, achieved through the use of a coaxial nanowire electrode. This avant-garde technology is particularly promising for applications in the heavy-duty trucking sector, having demonstrated significant resilience in stress evaluations.

A novel fuel cell design featuring superior endurance presents substantial opportunities for adoption in heavy-duty trucking, among other clean fuel cell applications. Comprising nanowires that demonstrate heightened resistance to corrosion compared to conventional designs, this innovative electrode is integral to a polymer electrolyte-membrane fuel cell. The technology is set to inaugurate a transformative phase for fuel cells, which rely on hydrogen to deliver emission-free energy for automotive applications.

According to Jacob Spendelow, a scientist part of the Los Alamos National Laboratory team that published its findings in the journal Advanced Materials, “The development indicates the possibility of crafting more resilient fuel cells that deliver efficient fuel consumption over an extended service life. The study showcases that conventional carbon-based catalyst supports can be successfully eliminated, thereby mitigating degradation issues related to carbon corrosion and yet maintaining high performance in fuel cells.”

Table of Contents

Application in the Realm of Heavy-Duty Trucking

The enhanced resilience of this fuel cell makes it an attractive option for integration into heavy-duty trucking systems, where a fuel cell lifespan exceeding 25,000 hours is critically important.

The Coaxial Nanowire Electrode (CANE) is constructed from an organized series of vertically aligned nanowires. Each individual nanowire consists of a catalytically active platinum film encapsulating an ion-conducting polymer core. By abstaining from the use of carbon-based catalyst supports, CANE sidesteps the conventional degradation processes related to carbon corrosion.

Assessments on Performance and Longevity

For assessing the durability of this novel fuel cell, the Los Alamos National Laboratory team executed accelerated stress tests. Impressively, CANE exhibited only a 2% performance reduction following 5,000 stress test cycles aimed at the support materials. This contrasts sharply with traditional carbon-based electrodes, which saw an overwhelming 87% plunge in performance.

It should be noted that this coaxial nanowire technology represents just one of several innovative fuel cell designs developed at Los Alamos National Laboratory; another example being a grooved electrode design recently covered in Nature Energy.

Reference and Funding Information

The research paper entitled “Coaxial Nanowire Electrodes Enable Exceptional Fuel Cell Durability” was authored by Gaoqiang Yang, Siddharth Komini Babu, Wipula P. R. Liyanage, Ulises Martinez, Dmitri Routkevitch, Rangachary Mukundan, Rodney L. Borup, David A. Cullen, and Jacob S. Spendelow, and was published on 19 June 2023 in Advanced Materials. DOI: 10.1002/adma.202301264

Financial backing for this project was provided by the U.S. Department of Energy Hydrogen and Fuel Cell Technologies Office (DOE-HFTO), in association with the Million Mile Fuel Cell Truck consortium. Further support came from the Laboratory Directed Research and Development program at Los Alamos National Laboratory. Part of this work was conducted at the Center for Integrated Nanotechnologies, a user facility operated by the U.S. Department of Energy Office of Science, and electron microscopy work was performed at the Center for Nanophase Materials Sciences, another DOE Office of Science User Facility, situated at Oak Ridge National Laboratory.

Frequently Asked Questions (FAQs) about fuel cell technology

What is the main innovation introduced by the Los Alamos National Laboratory?

The main innovation is a corrosion-resistant fuel cell design that features a coaxial nanowire electrode. This new technology is particularly promising for heavy-duty trucking applications and has demonstrated significant durability in stress tests.

How does this new fuel cell design improve durability?

The fuel cell uses nanowires that are less susceptible to corrosion compared to conventional designs. This increased resistance to corrosion contributes to the fuel cell’s superior durability, especially when compared to carbon-based catalyst supports, which are prone to degradation.

Who is the scientist from Los Alamos National Laboratory associated with this research?

Jacob Spendelow is the scientist from Los Alamos National Laboratory who is part of the team that described the results of this research in the journal Advanced Materials.

What are the practical implications of this fuel cell technology?

The enhanced durability makes the fuel cell a strong candidate for use in heavy-duty trucking, where long-lasting fuel cell longevity exceeding 25,000 hours is critically important. Additionally, it could find applications in various other clean fuel cell sectors.

What material replaces the carbon-based catalyst supports in the new design?

In the new coaxial nanowire electrode (CANE) design, a catalytically active platinum film surrounds an ion-conducting polymer core. By doing so, it avoids the use of carbon-based catalyst supports, thereby eliminating common degradation mechanisms associated with carbon corrosion.

What were the results of the durability tests performed on the new fuel cell design?

The team at Los Alamos National Laboratory conducted accelerated stress tests on the new design. The coaxial nanowire electrode lost only 2% of its performance after undergoing 5,000 stress test cycles, whereas a traditional carbon-based electrode experienced an 87% decline in performance.

What is the source of funding for this research?

The research was financially backed by the U.S. Department of Energy Hydrogen and Fuel Cell Technologies Office through the Million Mile Fuel Cell Truck consortium, as well as the Laboratory Directed Research and Development program at Los Alamos National Laboratory.

Where was the research published and who are the authors?

The research was published in the journal Advanced Materials on 19 June 2023. The authors include Gaoqiang Yang, Siddharth Komini Babu, Wipula P. R. Liyanage, Ulises Martinez, Dmitri Routkevitch, Rangachary Mukundan, Rodney L. Borup, David A. Cullen, and Jacob S. Spendelow.

More about fuel cell technology

- Advanced Materials Journal

- U.S. Department of Energy Hydrogen and Fuel Cell Technologies Office

- Million Mile Fuel Cell Truck Consortium

- Los Alamos National Laboratory

- Center for Integrated Nanotechnologies

- Center for Nanophase Materials Sciences at Oak Ridge National Laboratory

- DOI for the Research Paper

6 comments

Wow, this is a game changer for fuel cells! Finally, some1’s addressing the durability issue. can’t wait to see this tech on the roads.

As someone in the trucking biz, this is huge. Durability over 25,000 hours? That’s what we’ve been waiting for.

Mind-blowing research, guys. I’ve always thought fuel cells were the future, and this just cements it. The corrosion issue’s been a massive hurdle, glad to see it being tackled head-on.

Seriously impressive. Getting rid of carbon-based catalyst supports is a big deal. But I wonder how cost-effective this new material is? Anybody got any info on that?

Impressive. If this tech becomes mainstream, imagine how it could revolutionize clean energy! It’s high time we moved past fossil fuels, and this looks promising.

Just read the article. If this is as good as it sounds, I see a lucrative market ahead. Los Alamos, take my money!