Metal-organic frameworks (MOFs) are a class of compounds consisting of metal ions or clusters coordinated to organic ligands to form one-, two-, or three-dimensional structural networks. These porous materials have emerged as one of the most promising classes of adsorbents and catalysts for a variety of applications in gas storage, separation, and catalysis.

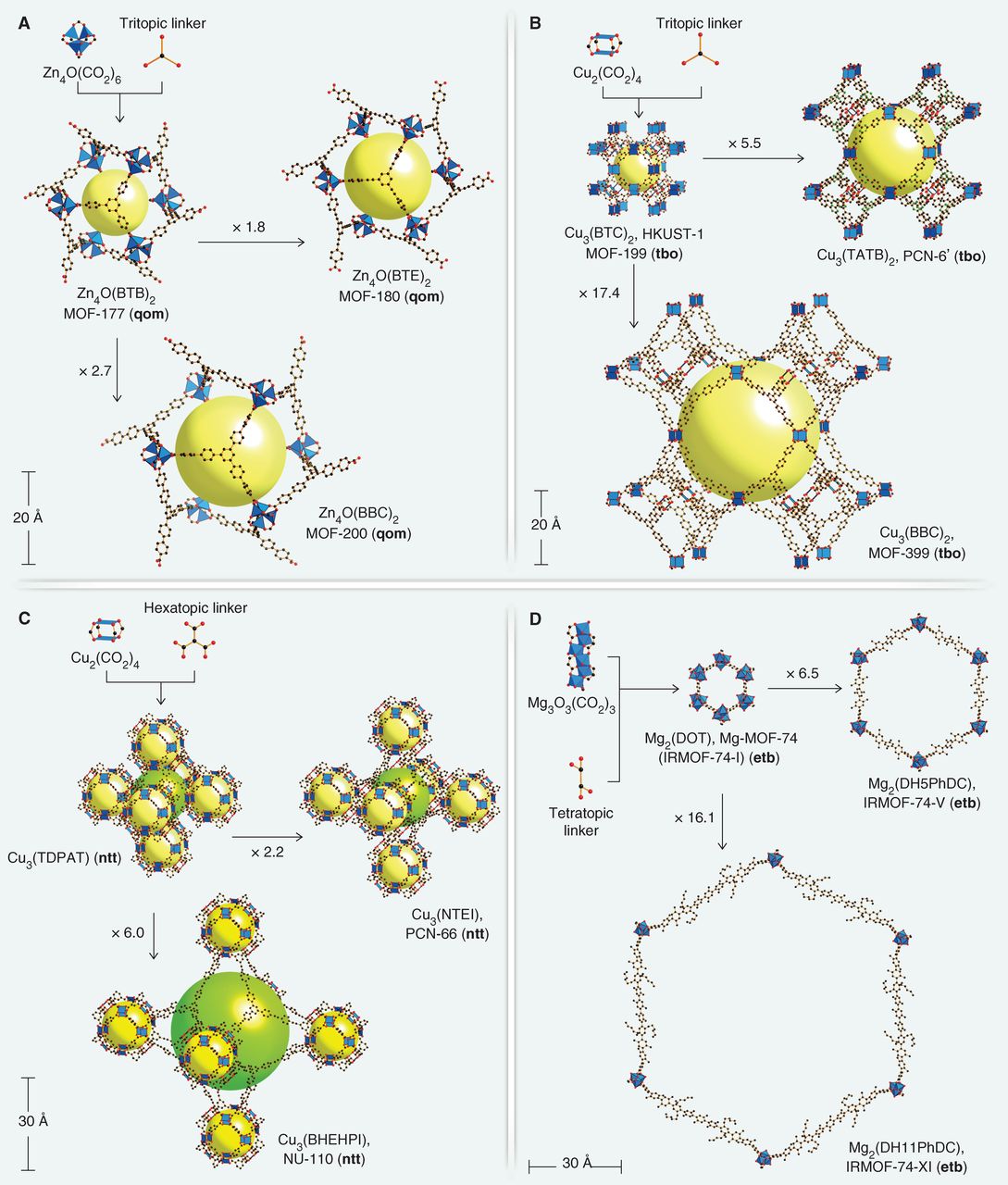

MOFs can be made using a variety of metals and ligands, which allows for considerable tunability in their properties. For example, by changing the metal or organic linker, it is possible to tailor the pore size, shape, and functionality of MOFs. This makes them well suited for use in a number of different separation and catalysis processes. In addition, many MOFs are highly crystalline and have large surface areas, which makes them ideal candidates for use as catalyst supports.

The first MOF was synthesized in 1992 by Yaghi et al.1 Since then, there has been an explosion in the field with over 30 000 unique structures now reported in the literature2–4 The majority of these materials are based on transition metals such as zinc(II), cobalt(II), nickel(III), copper(II), manganese(III), iron(III), vanadium(V), chromium(III), molybdenum(VI), tungsten(VI), uranyl(VI)5–7 and lanthanides8 but main-group metals9–11 and post-transition metals12 have also been used to prepare MOFs. In terms of organic linkers, polycarboxylates13–15 are the most commonly used but other functional groups such as phosphates16–18and sulfonates19–21 have also been employed successfully. More recently designed linkers include those that contain active sites for specific reactions22 or those that can undergo reversible changes in conformation23 which can lead to dynamic behavior24 during adsorption/desorption processes.