Researchers from the Massachusetts Institute of Technology (MIT) and the Institute of Science and Technology Austria have unveiled an innovative technique to simplify the construction process of intricate materials known as cellular metamaterials. This breakthrough involves a unified graph-based representation that encompasses diverse building blocks, enabling engineers to effortlessly design, edit, and simulate metamaterials.

Cellular metamaterials, composed of repeating units or cells in various patterns, hold immense potential for engineering applications. These materials can offer unique combinations of mechanical properties, such as exceptional strength and lightweight characteristics for more fuel-efficient transportation, or porous and biomechanically friendly attributes for medical implants.

However, the challenge lies in determining the ideal cellular structure to achieve specific properties, given the vast array of possible arrangements, even when considering smaller building blocks like interconnected beams or thin plates. Manual exploration of all potential cellular metamaterials is practically impossible due to this complexity.

To address this issue, MIT and IST Austria researchers have developed a computational method akin to a specialized CAD system tailored for metamaterials. This method empowers engineers to swiftly model highly complex metamaterials and experiment with designs that would traditionally take days to create. Furthermore, the user-friendly interface grants access to the complete spectrum of potential metamaterial shapes, making it a versatile tool for engineers.

The key innovation behind this approach is a representation that covers a wide range of shapes relevant to engineers’ interests. Instead of limiting exploration based on preconceived notions, this method embraces the full diversity of metamaterial shapes. By representing cellular metamaterials as a graph structure, the researchers offer a flexible framework for users to construct metamaterial skeletons using vertices and edges. For example, a beam structure is created by placing vertices at each endpoint and connecting them with a line, with the option to adjust the thickness along the beam.

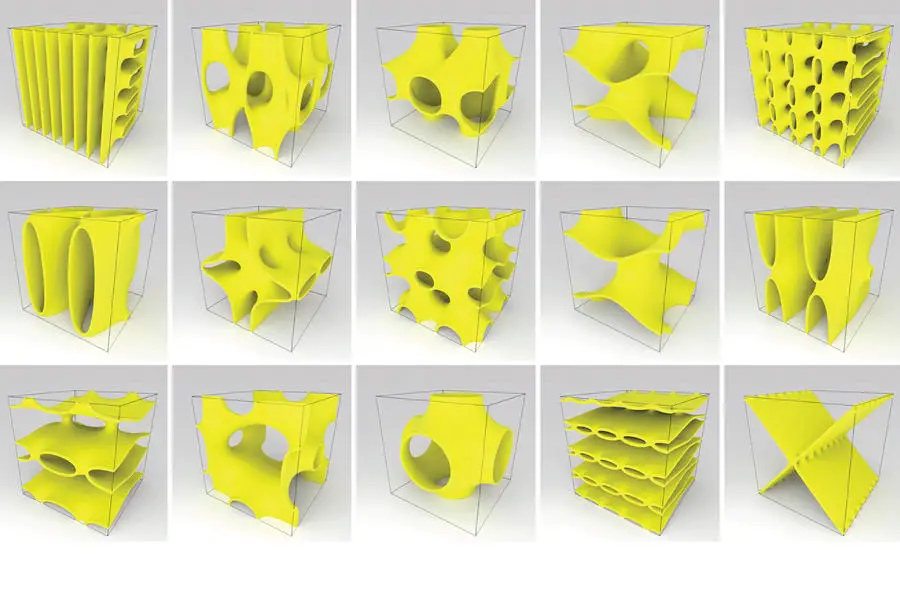

The system also includes solvers for surfaces, allowing users to mark important features with vertices and then employ a solver to infer the remaining surface. The system’s flexibility even extends to constructing complex metamaterials like triply periodic minimal surfaces (TPMS), which are typically challenging and time-consuming to develop.

Notably, the system maintains a detailed record of the entire design process, including vertices, edges, solvers, transformations, and thickening operations. Designers can preview their structures at any stage and predict properties like stiffness, facilitating an iterative design process.

In testing, the researchers demonstrated the system’s capability to generate various classes of metamaterials efficiently. They also implemented automated exploration algorithms, significantly accelerating the design process. A user study confirmed the system’s user-friendliness, even for individuals with limited experience in metamaterial modeling.

Looking ahead, the researchers aim to further enhance their technique by incorporating more complex skeleton thickening procedures to broaden the range of achievable shapes. Additionally, they plan to explore the use of automatic generation algorithms. Ultimately, their vision includes utilizing this system for inverse design, where material properties are specified, and algorithms find the optimal metamaterial structure.

This pioneering research has received support from several entities, including the National Science Foundation, MIT Morningside Academy Design Fellowship, Defense Advanced Research Projects Agency (DARPA), ERC Consolidator Grant, and the NewSat project. The findings are published in the ACM Transactions on Graphics journal.

Table of Contents

Frequently Asked Questions (FAQs) about Metamaterial Design

What is the key innovation in this research?

The key innovation in this research is the development of a computational technique that utilizes a unified graph-based representation to simplify the design of cellular metamaterials. This technique enables engineers to quickly model complex metamaterials and experiment with different designs.

What are cellular metamaterials, and why are they important?

Cellular metamaterials are artificial structures composed of repeating units or cells in various patterns. They are essential because they offer the potential to achieve unique combinations of mechanical properties, such as strength, lightweight characteristics, and porosity. These materials have a wide range of applications, including aerospace, automotive, and medical fields.

How does the graph-based representation work in designing metamaterials?

The graph-based representation allows users to construct metamaterial skeletons using vertices and edges. For instance, for a beam structure, vertices are placed at each endpoint and connected with a line. Users can adjust parameters like thickness along the beam. This approach offers flexibility in designing various metamaterial shapes.

What advantages does this research offer to engineers and designers?

This research provides engineers and designers with a user-friendly interface for rapidly creating complex metamaterial structures. It significantly reduces the time required for design and experimentation, making it easier to explore a wide range of potential metamaterial shapes and properties.

What is the significance of maintaining a detailed record of the design process?

Maintaining a detailed record of the design process, including vertices, edges, solvers, transformations, and thickening operations, allows designers to track and understand every step of their metamaterial creation. This record-keeping aids in the iterative design process and facilitates property predictions, such as stiffness.

Are there plans to further improve this technique?

Yes, the researchers plan to enhance this technique by incorporating more complex skeleton thickening procedures to enable the modeling of a wider variety of shapes. Additionally, they intend to explore the use of automatic generation algorithms. Ultimately, the goal is to utilize this system for inverse design, where desired material properties are specified, and algorithms find the optimal metamaterial structure.

More about Metamaterial Design

- MIT News: “Metamaterial Magic: New MIT Method Simplifies the Construction Process for Complex Materials”

- ACM Digital Library: “Procedural Metamaterials: A Unified Procedural Graph for Metamaterial Design”

3 comments

wow, cool stuff bout makin’ stuff. i thnk these new materils cud make things bettr.

this gr8 for innovation. gud job mit & ista. more metamats in future, pls!

i luv how they made it so easy for engs to design complex stuff. need more tech like this!